Prepare the Soil

Before the journey to lean can begin, the organization must engage in a variety of preparatory activities. These include not only mapping the current and future state and developing the business case for future action, but establishing a Charter, which serves as a roadmap for implementation and defines the roles and responsibilities of those navigating the path to lean. In addition, preparation focuses on creating a vision and beginning work with leadership to assure commitment, alignment and action toward the future state.

Stability

The focus of the first phase is to highlight and recognize instability, so that problem solving can begin. The emphasis is in establishing supervisory authority, instilling a sense of urgency to solve problems, and creating a visual workplace so that those problems become visible. By the close of this phase, the organization must have the ability to see instability, and the skill and knowledge to react to it appropriately.

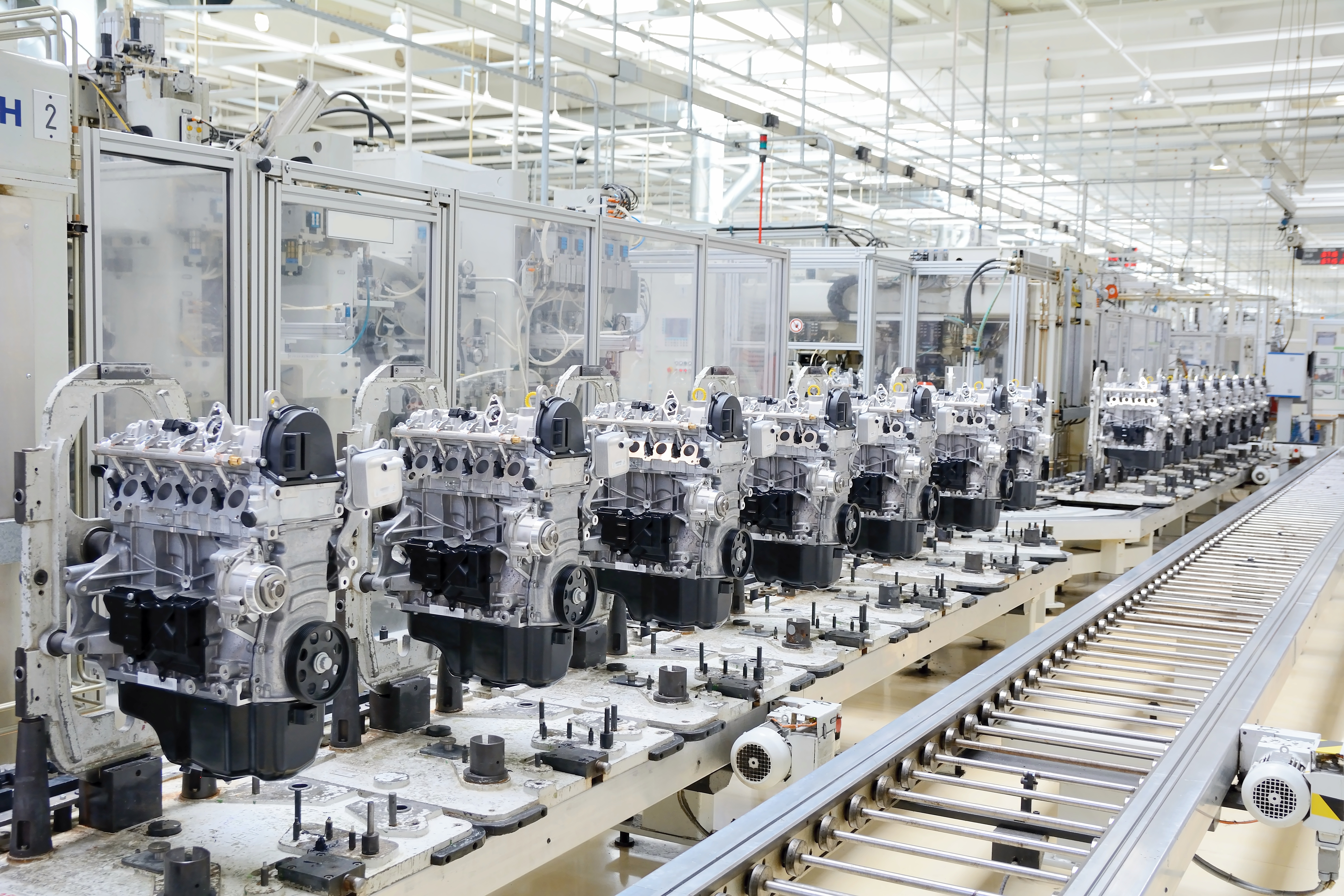

Continuous Flow

In this phase, the objective is to create continuous, unstopping movement from task to task. Flow is typically interrupted by equipment, process or material. Therefore, each of these elements is examined, and tools are developed to overcome those interruptions. At the close of this phase, processes should flow from task to task, at their natural rate.

Synchronous Production

The objective of this phase is to adjust the flow of processes to the rate of customer demand. Work is redistributed so that each process is completed within this rate, and as work is rebalanced, each task within the process is documented into a standard. Then, from that time forward, the visual representation of that process is used to compare the actual to the standard.

Pull Systems

Once the process flows at the rate of customer demand, the next objective is to pull the product through the various processes, while pulling material from suppliers. This phase is focused on maintaining smooth and even flow, but to do so by pulling production from process to process, where only those parts just necessary for the next production process are at the ready. This, in turn, sets the requirement for the suppliers to provide material at the rate of its actual use.

Level Production

Once the organization is capable of producing at the rate of customer demand, the next stage of improvement is reached by focusing upon the way production is scheduled. The objective is to build product in the exact sequence ordered, leveled in volume, mix and sequence, over a fixed period and equal to customer demand. In this final phase, the organization encounters the greatest challenge to reduce the time from order to completion. Success results in shorter lead time and greater flexibility in meeting customer demands.