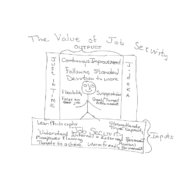

The Role of HR in a Continuous Improvement Organization: The Attainment of Job Security

(Reposted by permission of the author from LinkedIn)

At the foundation of the implied agreement between the employee and their company is the notion that job security is achieved as a result of the contribution of those who add value. In practice this is very difficult because no single company can guarantee a job for life. Economic conditions can cause such major disruption to companies that a guarantee is beyond their attainment. If this is so, then the management of the balance between inspired action and company success is the link that must be present for success. How they manage job security will determine their long-term success.

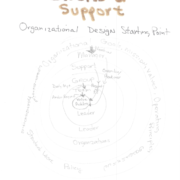

All companies rely on leadership to understand the future effect of external forces to the organization and be able to put in place proactive initiatives that preserve the workforce. In the past, this practice was seldom attained and as a result the first reaction to a downturn in business was to lay off those people who create product. If leadership is focused on job security, the long-term effect of market cycles can be mitigated.

At Toyota, we had a different mandate. Leadership is entrusted with the future. As the economy progresses, actions can be taken to mitigate the effects of a downturn. What is different is that those who add value to the product will be protected for the company to achieve its mission. When leaders accept this mission, it is clear that those who add value are the most important. Pro-activity is required to achieve the mission and job security. Robert Greenleaf would consider this servant leadership.

So, what kind of actions are taken to ensure that those who add value are the most important? It starts with the planning for manpower. Manpower is a compelling financial expenditure and if it is out of control the business can be seriously harmed. Manpower planning is one of the most important in the series of events conducted during the planning period. The skill of manpower planning is to predict what will likely happen with turnover, retirements and movements to different teams in the context of the amount of value added required to meet forecasted customer demand. This seems like a pure hunch to determine but underlying this is the notion of true capacity. True capacity is volume of work that can be accomplished. To determine true capacity, standard work becomes the guiding measure of capacity and the process execution tool for calculating it. It can be determined with a great deal of certainty, thru pilot where standard work is first determined, in production control where volume is determined based on sales forecast and on the line where standard work is realized due to the use of the andon. Andon is a learning device that allows problems to be easily lifted up and countermeasures achieved. With all of these aspects of the production system working toward achieving predictability, the amount of labor required can be precisely calculated.

The support labor can be determined based on the production system’s value-added capacity with a ratio of activity to support production based on replenishment and andon pulls or with a historical analysis of the expectation for support to meet the pre-determined percentage of the labor budget. This is added along with scheduled actions such as launches, product changes, and known events such as planned shut downs to complete a full analysis.

These elements create the certainty that labor can be precisely calculated by position and organizational unit. This gets turned into a manpower plan authorized and controlled by HR. From this, HR can plan and execute hiring to have individuals ready at the time they are needed (just in time).

The second way job security is sustained is through the use of continuous improvement. There is a development process to bring the value adder into the mindset joined with leaderships expectation to improve every day. This is supported by expectations set by leadership, first, for the level first of participation in continuous improvement in the process and later extended to the reduction in the number of processes. Keep in mind that the reduction in the number of processes has an equivalent impact on product dock to dock time. This allows the company to deliver faster to a schedule to meet customer demand and provides a buffer that supports changes in takt time based on orders.

As the takt time is determined by the volume, changes can alter the speed with less processes needed. When a position is eliminated as a result of continuous improvement, that person is moved to another open position or to a continuous improvement team. In fact, going to continuous improvement teams is valued by the team members.

The third way to protect job security is to set targets for the team member for achieving improvement, not by force, but by limiting the improvements to the job of each individual. This creates the environment for each and every member to contribute to the improvement by retaining the accountability for improvement. Members accept improvement as a logical expectation for their job as a means to support job security. This reduction in process content results in a re-balance to takt time & is accomplished by the members as they rearrange tasks to accommodate the reduction of non-value-added task to the takt time.

The fourth primary way of achieving job security is rooted in the orientation process conducted by HR. During this process members are told that job security is the intention but cannot be guaranteed. They are told that the control over job security that is possible is based on two things; their continuous improvement of the job and the policy for how layoffs will be determined. Layoffs will proceed in the following order:

- First priority is the increase continuous improvement activity

- Second is the bringing of contracted services back into the plant and eliminate non-essential hiring

- Third is the reduction of management bonuses

- Fourth is the layoff of non- value-adders and management personnel

- And fifth is the layoff of value adding personnel

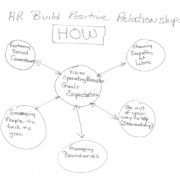

This list is the commitment of the organization to the members. It is then a matter of trust. Members are told how mutual trust and respect is a fundamental value of the organization. It is from that value that member experience job security aided by oversight of HR. Violations of mutual trust and respect are handled by HR with speed and seriousness to demonstrate its importance.

The fifth way job security is protected is within the job environment. It takes up to 20 weeks for the member to be put on the job full time. This time is spent conditioning for the grueling work and learning their job in a way that brings to life the importance of quality. By initially experiencing the care that is taken to get members fully on the job and the attention to ergonomics coupled with constant interaction, HR gets to know each member creating an environment that is warm, supporting and accepting. The member develops a belief in job security and job security.

The sixth way job security is sustained actually begins before any work is accomplished. The plant is designed for a specific volume level. It is staffed at 80% of that volume and fluxes in actual volume are controlled by takt time and overtime. This is important because most companies go after volume and will distort the production process to accomplish higher volumes. Many times, additional people are added to accommodate the higher volumes only and are considered the first to go during reductions in volumes.

By protecting the value adding members, the ebbs and flows of volume will not affect job security until the volume is less than 60% of the expect capacity. During these periods of low volume key decisions can be made to protect job security. The plant is set on no output and training is conducted to keep the members learning. This short-term cost is offset by the productivity achieved later by the members as they are motivated to do continuous improvement.

It is true that having a contract workforce of some specified number allows flexibility in periods of downtime. However, these employees are not treated differently. They are part of the family, operate to the process expectation exactly like regular members and are governed under the same policies with minor exceptions. Because they are hired on the basis of business volume just the same as members, their contribution is vital. Every attempt is made to have them experience job security and to feel they are just as important as the members when they are performing their standard work. Additionally, they have the incentive that they too can become members over time given acceptable levels of performance of standard work and continuous improvement. They are not distinguished from the other members. They experience what a member experiences.

If job security is important to the members, then it follows that it is part of the system of work and not an afterthought. All the actions and activities are planned with job security in mind for the mid and long-term. All the interactions with policy and support personnel are constructed to achieve a positive exchange with all members who add value. Job security is an important element of the system of work and one that encourages members to be at work all day every day, improve their process and follow the policies that are designed to achieve personal accountability. In this environment job security is seldom discussed or thought about. It is in the air.

At the most fundamental level of the psychology of the member, job security is valued. Companies that protect this get inspired action from the members. Just remember the member knows when volume is down and will ‘test” leadership during difficult times to find their commitment. I have seen whole plants slow down just to protect their members by taking the available work and individually allocating more time to their process. This may have short term benefits to the members in the short run but it brings additional cost into the product which lessens job security. A thoughtful approach to job security plus informed interaction and expectations with and for the member will, in the long run, give the organization its best chance for longevity and enhanced job security. It is very clear that HR must accomplish this culture to be successful.

2019, Total Systems Development, Inc.

2019, Total Systems Development, Inc.

2019, Total Systems Development, Inc.

2019, Total Systems Development, Inc. 2019, Total Systems Development

2019, Total Systems Development

2019, Total Systems Development, Inc.

2019, Total Systems Development, Inc.