Introduction to TSD’s 5-Phase Implementation Model

The search for a consistent methodology to implement lean led me to many diverse places. I considered the work of many famous management development gurus and the work on systems by my good friend Herman Gyr. While at Toyota I became aware that there is a logical architecture to lean implementation. In trying to reconcile what I saw and heard, my desire was to create implementation that fit the systematic ways of lean.

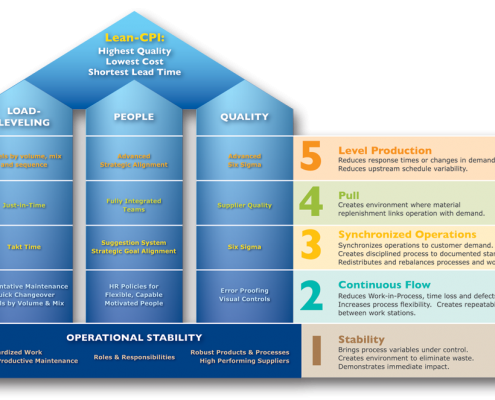

When we were introduced to the work of the Toyota Supplier Support Center, we knew that the ultimate truth lay in the development of the business systems. These provided the purpose of the lean implementation. This understanding contributed the most to the Five Phased Implementation process. If they were aligned, then the purpose of any organization could be achieved. This led to our detailed model, the Roadmap. The work by the Toyota Supplier Support Center was central to our understanding of the implementation process. We provided the detail that allows our consultants to effective achieve the purpose of the organization.

When we were introduced to the work of the Toyota Supplier Support Center, we knew that the ultimate truth lay in the development of the business systems. These provided the purpose of the lean implementation. This understanding contributed the most to the Five Phased Implementation process. If they were aligned, then the purpose of any organization could be achieved. This led to our detailed model, the Roadmap. The work by the Toyota Supplier Support Center was central to our understanding of the implementation process. We provided the detail that allows our consultants to effective achieve the purpose of the organization. Over the years our roadmap was populated with all the tasks necessary to implement the Five Phase. However, we came to the conclusion that in our work we need a Phase Zero to align leadership to the work to be done. We created a Phase Zero as a formal process that includes an assessment, a Charter, a business case and a project plan. These became prudent as a continuous reminder to all what the reason for the implementation was and a demonstration of our commitment.

Over the years our roadmap was populated with all the tasks necessary to implement the Five Phase. However, we came to the conclusion that in our work we need a Phase Zero to align leadership to the work to be done. We created a Phase Zero as a formal process that includes an assessment, a Charter, a business case and a project plan. These became prudent as a continuous reminder to all what the reason for the implementation was and a demonstration of our commitment. Phase one is called Stability and it simply means that the organization cannot make progress until it is able to identify instability. Instability comes from using random processes that generate variability. The target is to accomplish the ability to see and react to all forms of variation. The two key issues are quality and problem solving.

Phase one is called Stability and it simply means that the organization cannot make progress until it is able to identify instability. Instability comes from using random processes that generate variability. The target is to accomplish the ability to see and react to all forms of variation. The two key issues are quality and problem solving.

The second phase is called Continuous Flow. The aim is to find and eliminate all forms of waiting & inventory embedded into the current process. This includes change over, inventory super-markets, etc. The target is to have flow at whatever rate the process can flow.

The second phase is called Continuous Flow. The aim is to find and eliminate all forms of waiting & inventory embedded into the current process. This includes change over, inventory super-markets, etc. The target is to have flow at whatever rate the process can flow.

The third phase is Synchronized Operations. This is characterized by getting a process that flows at the rate of customer demand called Takt time. Standardized work becomes the most important component. What happens when you achieve synchronized flow is that the support issues come to the surface for material and equipment. In each of these first phases, you will find that you will have to go back on a periodic basis to the basics and verify standard work, job instruction and problem solving. We call this “back to the basics”.

The third phase is Synchronized Operations. This is characterized by getting a process that flows at the rate of customer demand called Takt time. Standardized work becomes the most important component. What happens when you achieve synchronized flow is that the support issues come to the surface for material and equipment. In each of these first phases, you will find that you will have to go back on a periodic basis to the basics and verify standard work, job instruction and problem solving. We call this “back to the basics”.

The fourth phase is called Pull. The objective of this phase is to have all processes that flow at the rate of customer demand to only begin production of the product from the upstream process when they have finished their process and are ready to produce. This act of pulling is aimed at the smooth flow of product and the reduction of inventory.

The fourth phase is called Pull. The objective of this phase is to have all processes that flow at the rate of customer demand to only begin production of the product from the upstream process when they have finished their process and are ready to produce. This act of pulling is aimed at the smooth flow of product and the reduction of inventory.

The fifth phase is called Level Production . It is process of leveling out production on the basis of volume, mix and sequence. It is another level of precision that highlights any flow that is not in sequence.

The fifth phase is called Level Production . It is process of leveling out production on the basis of volume, mix and sequence. It is another level of precision that highlights any flow that is not in sequence.

This is just the surface of the Five Phases. It is an enabler but not the answer. Nothing will take the place of critical thinking using the 5 phases. We have captured the detail of implementation in our roadmap and the next pieces will explore it. This is an enabler for both our consultants and our customers.